The recent implementation of tariffs on steel and aluminum by the U.S. government has triggered significant disruptions across multiple industries, particularly in automotive manufacturing. Below is an analysis of key developments and their implications.

Key Developments and Impacts

| Factor | Details |

|---|---|

| Tariff Implementation | A 25% tariff on steel and aluminum was announced, with no exemptions, affecting various import goods, including automobiles. Additional tariffs take effect on April 2. |

| Impact on Automotive Industry | The U.S. automotive sector, which heavily depends on imported steel and aluminum, is expected to face higher production costs. |

| Financial Effects | Vehicle prices are estimated to increase by approximately $6,500, shifting the burden to consumers. |

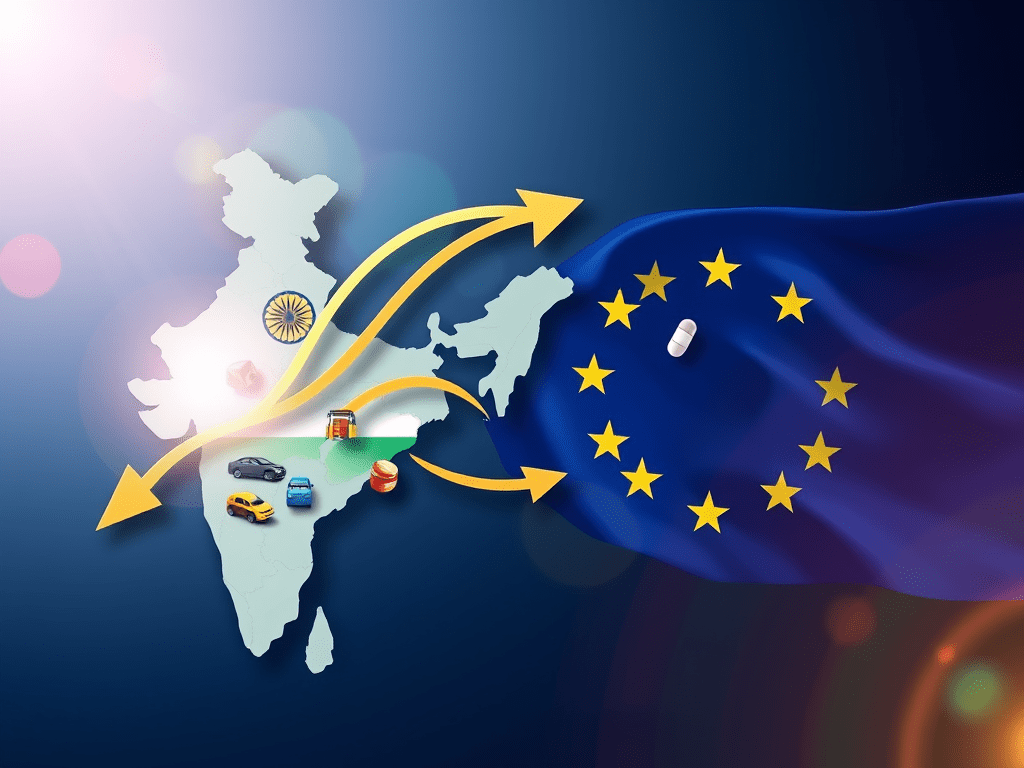

| Supply Chain Dependency | Major imports of steel come from China, India, Mexico, Italy, and Germany, leading to vulnerabilities in the supply chain. |

| Retaliatory Measures | Canada and the EU have imposed retaliatory tariffs on $49 billion worth of U.S. goods. |

| Ongoing Trade Tensions | The trade dispute extends beyond steel, affecting U.S. exports such as beef and pork due to retaliatory tariffs from China. |

| Future Supply Chain Strategies | Companies may need to explore alternative sourcing options to reduce dependency on China and mitigate geopolitical risks. |

Broader Implications

The steel and aluminum tariffs mark a key battleground in global trade tensions. While the policy aims to protect domestic manufacturing, the automotive sector may face significant financial strain. The potential rise in vehicle costs and retaliatory actions from trade partners highlight the complexities of economic nationalism. Going forward, businesses must adopt adaptive supply chain strategies to navigate these evolving trade dynamics.

Leave a comment